Walther

NOTE:Walther tends to make small "continuous product improvement" changes that can have unintended consequences for aftermarket manufacturers like us. (Meaning there's nothing "wrong" with your Walther, but your Walther might be slightly different than our Walthers.)

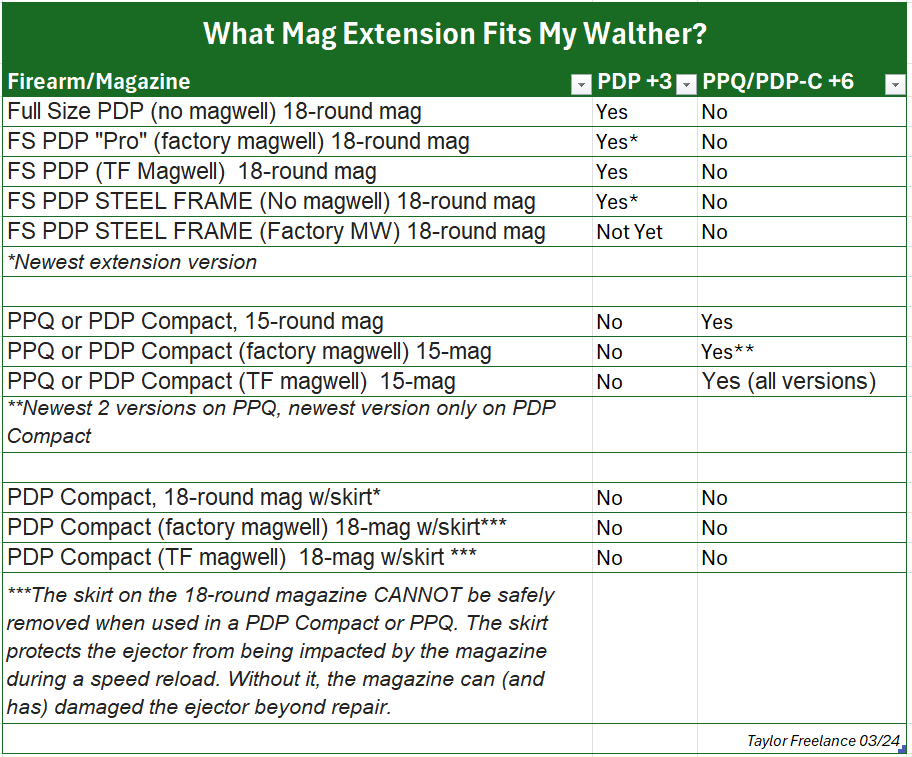

NOTE: 18-round mags, they are not extendable. If you remove that collar around the bottom of the mag, the mag will overpenetrate and collide with your ejector during a slide-lock reload, potentially breaking the ejector.

|

Walther Magwell / Over Penetration issue

Walther has changed the magwells on PPQ again. If you are having problems, please contact us Walther 10 round mag differences There are two types of 10-round mags. One looks like standard mag, but has a big dimple or dent pressed into each side to prevent it taking the full amount of ammunition. The other uses a short magazine tube attached to a tall plastic baseplate (using the basepad to make the short magazine as long as a standard one). Our Competition basepads work with the dent-in-the-side style, but not the short-mag-tube style. If you can find some of the dent-in-the-side variants, we strongly recommend those for a number of reasons. Here's what I found in a few minutes' looking: Tall basepad type (bad): Walther PPQ M2 9mm 10-Round Magazine (gunmagwarehouse.com) Dent-in-the-side type (good): Walther PPQ M2 / PDP / Q5 M2 9mm 10 Rd. Magazine, Anti-Friction Coating: MGW (midwestgunworks.com) Walther PDP Pro Our Walther PDP 140mm mag extensions and the Walther PDP +0 Competition extensions will fit the PDP PRO. At checkout, please leave a note that you want these parts for a PRO. WALTHER: My SF magwell is loose? We just learned that the PPQ SF frame dimensions aren't fixed in stone the way the polymer frames are. Worse, the portion of the SF frame that we used to anchor the magwell is not controlled by the machinists in Germany. As a result, some of the magwells fit great, others not so much. Depending on how loose the fit is, you've got options for fixing it. If it's just barely loose, you might want to shim the frame with a strip of electrician's tape (or similar), or some form of filler putty. If that doesn't immediately sort it, we've created a special magwell that can be fitted to the frame by the end user. The tab that holds it on is left unfinished, so you can mount the magwell and use a drill to finish the tab at exactly the right depth. We call that the "X" model, and would be happy to send you one if that's the direction you want to go. The crosspin for my magwell won’t go in Normally nothing has to be modified, but sometimes issues come up. As for the type of file, there's no particular standard -- the only trick is finding one thin enough to get inside that slot. You shouldn't have to remove much at all. Just to be double-sure, check the date code on the magwell. If it's got an "X" in it, that's the special mount version, and should be swapped out for a regular one. WALTHER +6/+12: I only get +2! Two ways you can end up only getting +2: Did you take the internal locking plate out and set it aside? The follower may be catching at the transition between the mag tube and the basepad. If that's the case, you can put a slight bevel on the tail of the follower and at the top-inside-rear of the basepad to allow the two parts to slide past each other -- it's the same basic problem as shown in this video about M&P mags -- https://www.youtube.com/watch?v=Tj40xkwPWiA&t=71s There is a possibility that the spring has rolled past 90 degrees during assembly. If so, the end of the spring is twisted sideways, blocking the rest of the spring from nesting properly. When this happens, the floorplate will want to aggressively push itself back into place when you start to slide the basepad off. The basepad will still come off, but it's a bit of a struggle. Do your mag extensions work with 20-round PPQ magazine and your magwell? 20 Round Mags fit? = Yes, but you will have to fit them to the magwell. Here's a little how-to video. https://youtu.be/xZ1yjlQcnhk The stock pads work great once they're modified, but if you don't want to do that, you can just buy +4s from us -- they're ready to go out of the box. |